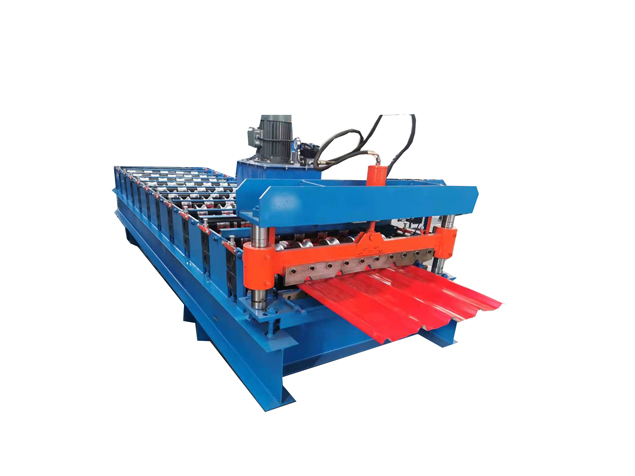

Glazed tile forming machine

As the manufacturer of the roll forming machinery, we can produce most of the products according to your requirements, it provides the customization.

- Working diameter: 1-80mm

- Max working length: 6m

- Description

The Color profiled steel plate rolling forming machine is a profiled plate that adopts color coating steel plate and is rolled and cold-formed into various wave shapes. It is suitable for industrial and civil buildings, warehouse special buildings, and large-span steel structure houses. Wall decoration, etc., has the characteristics of light weight, high strength, rich color, convenient and fast construction, earthquake resistance, fire resistance, rain resistance, long life, and maintenance-free. It has been widely promoted and applied.

The Working Flow of the glazed tile roll forming machine

Manual uncoiler—feeding device—rolling form—speed, length, pieces set by PLC—hydraulic mold post cutting—collection table.

The Working Flow of the glazed tile roll forming machine

Manual uncoiler—feeding device—rolling form—speed, length, pieces set by PLC—hydraulic mold post cutting—collection table.

- Parameter

| No. | Item | parameter |

| Machine model | DMC-1000 | |

| 1 | Material of Spindle | 45#steel |

| 2 | Shaft diameter | 70mm Solid shaft |

| 3 | Voltage | 380v/50hz three phase |

| 4 | Forming Speed | 8-12 m/min |

| 5 | Number of forming rows | 11 rows |

| Transfer method | Chain drive | |

| Main motor | 4kw | |

| 6 | Cutting method | Hydraulic cutting |

| 7 | Hydraulic pump station power | 4kw |

| 8 | Medium plate thickness | 12mm |

| 9 | Blade material | with Cr12mov blade High temperature quenching 58° |

| 10 | Roller material | 45# steel forgings CNC finishing surface polishing and plating |

| 11 | Machine frame | 300H steel |

| 12 | Pressing thickness | 0.3-0.8mm Prepainted galvanized steel coils |

| 13 | Feeding width | 1200mm |

| Dimension for first machine | 6000mm*1500mm*1100mm | |

| Dimension for second machine | 8500mm*1500mm*1100mm | |

| Number of forming rows | 11rows for first machine | |

| Number of forming rows | 20rows for second machine |